Innovating family business

SMO designs, builds and sells machines for the food industry under the brand name PINTRO. PINTRO builds both off the shelf and custom made machines. Its clients consist of small businesses as well as industrial production companies.

PINTRO specialises in skewering machines, meatball and burger patty shapers. SMO, its parent company’s core business is custom built machines.

Having the engineering department, the workshops and the sales team in-house allows us to react quickly. A strong 50-man team of highly skilled and motivated colleagues stands ready to deliver superior quality products, but also pre- and after sales service at any time. This combination leads to a successful long term client relationship.

Sander Mollet created his company in 2002. He quickly noticed that he would be needing more people. In less than two decades almost 50 more colleagues joined SMO. That includes Sander’s brother Lode (co-owner), his mother Greet and his father Jos.

The ever challenging (new) projects combined with the family-like environment provide a pleasant working atmosphere which encourages every member to give his best every single day!

Although the initial focus lied on custom built machines, today the off the shelf products have gained more importance. SMO includes a number of own brands that each have their dedicated management. PINTRO, WIWAM, GreenGen and FleXiever. Sander’s continuous investments in these different departments start to yield positive results.

Why choose PINTRO?

An own ENGINEERING DEPARTMENT consisting of specialists in every field.

Our engineering department consists of young and motivated team members who continuously attend trainings that keep them up to date on the latest techniques.

Engineers and technical drawers

Engineers and technical drawers closely work with the client to develop and design concepts. We pay great attention to and always adhere to the food industry’s strict hygiene, safety and ergonomics requirements.

Electrical department

Thanks to extended experience there are few secrets left for our electrical engineering department. The design of the electrical cabinets, its contents and development are all created and assembled in-house.

Automation and programming

The automation and programming department always focuses on the best possible, user friendly solution. The functioning and user interface are all programmed at our team.

Own WORKSHOPS equipped with modern machinery

We dispose of two spacious workshops with several lathes, cutters, slotting machines, drills, grinders and straighteners. In a separate workshop we operate our metal saws and welding installations.

Our own competent MECHANICS and FITTERS

Noting is too complex for our mechanics and fitters team! They install and adjust your machines to the highest standards.

Multilingual SALES team

Our multilingual pre- and aftersales department provides a professional follow-up for all your questions. We are willing to visit you for a demonstration and/or to meet you to discuss your project.

The LOGISTICAL department manages all national and international shipping and administration.

PINTRO history

2002

Founding SMO

Sander Mollet establishes his own company.

2007

Idea skewering machine

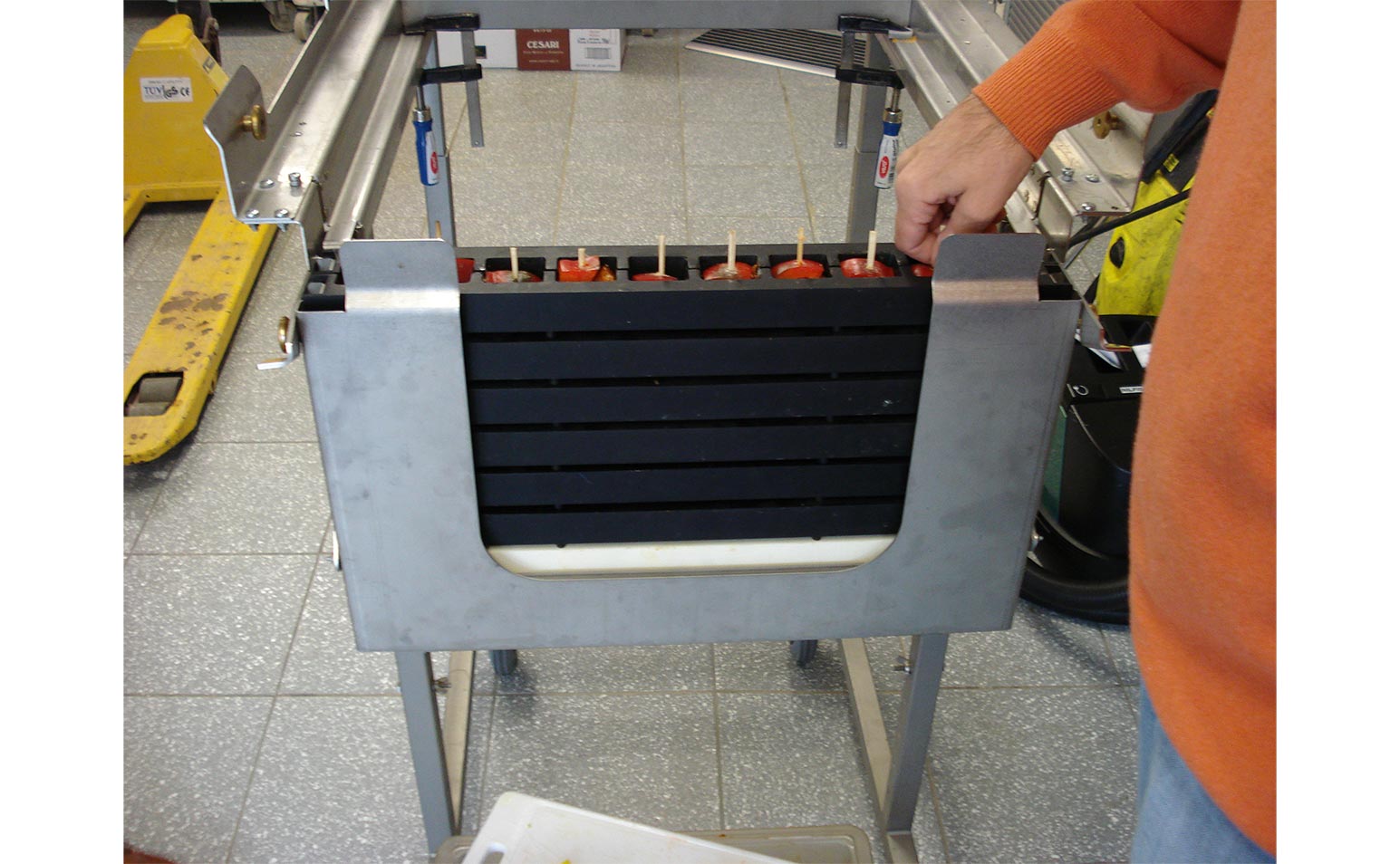

Leo Bertens – butcher by trade– presents his idea of designing a machine that would make traditional style skewers efficiently and ergonomically. It initially looked like this.

2010

First manual PINTRO ready

The first manual PINTRO was ready to be tested and presented to a number of important potential clients. We quickly came to the conclusion that size and ergonomics need to be addressed.

2012

Creation brand name PINTRO

Creation of the brand name PINTRO which was derived from the English verb “pin through” or pierce

2012

``PINTRO mini`` and Burger patty former

Development and fine tuning of the “PINTRO MINI”, a manual table top machine jump-starts PINTRO’s commercial activities.

Following a request from our Belgian distributor SMO builds a hamburger patty shaper, today’s HBF700

2013

Current manual machines on the market

Further improvements and developments to the PINTRO MINI which result in the creation of our current PINTRO P160, P480 and P720

2014

Extension sales team & development of semi-automatic skewering machine

Extension of the sales team

Start of the semi-automatic PINTRO P1000 skewering machine’s development

2015

Development Meatball former & new PINTRO look

Development of the meatball former

Design of a new logo

2016

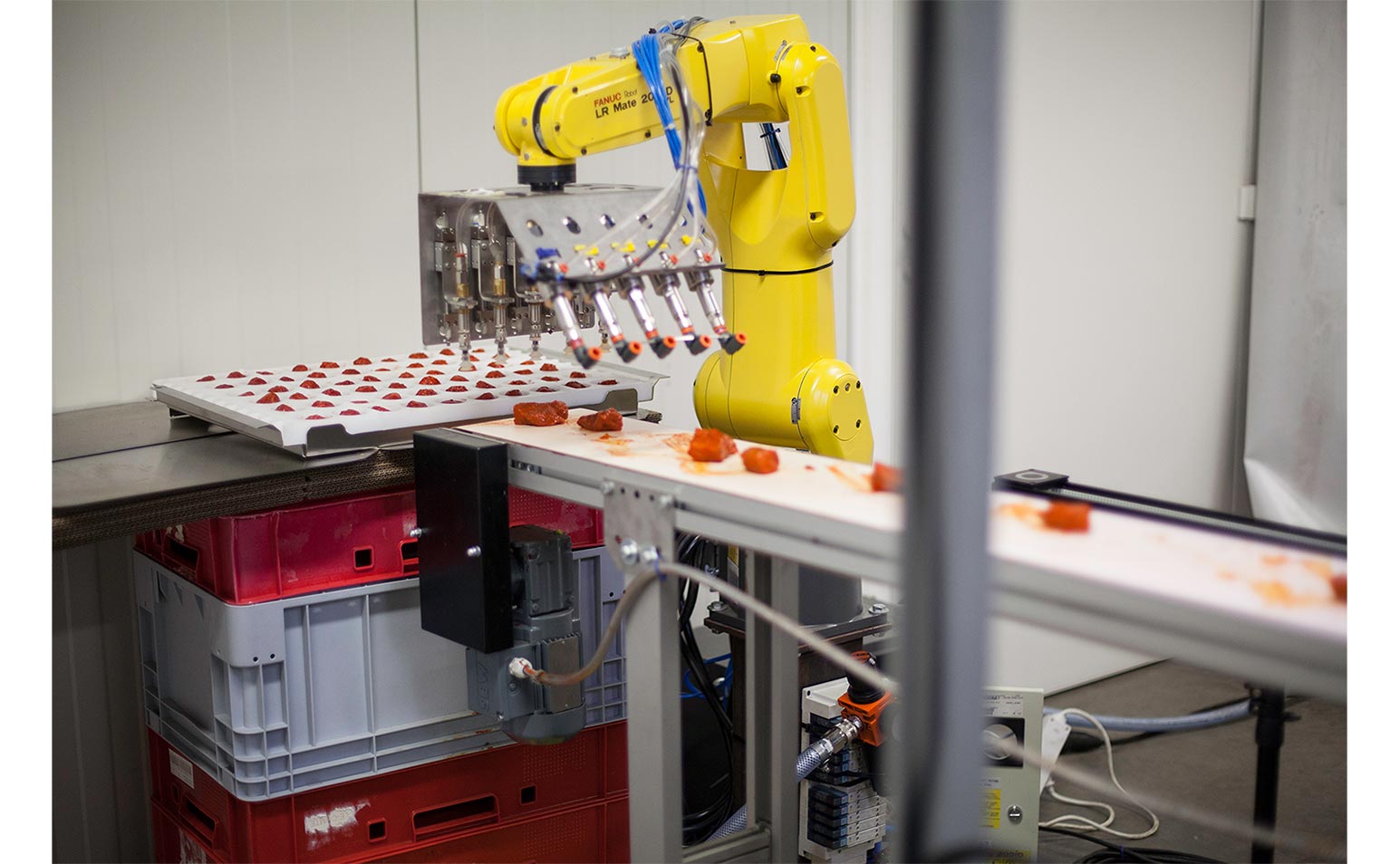

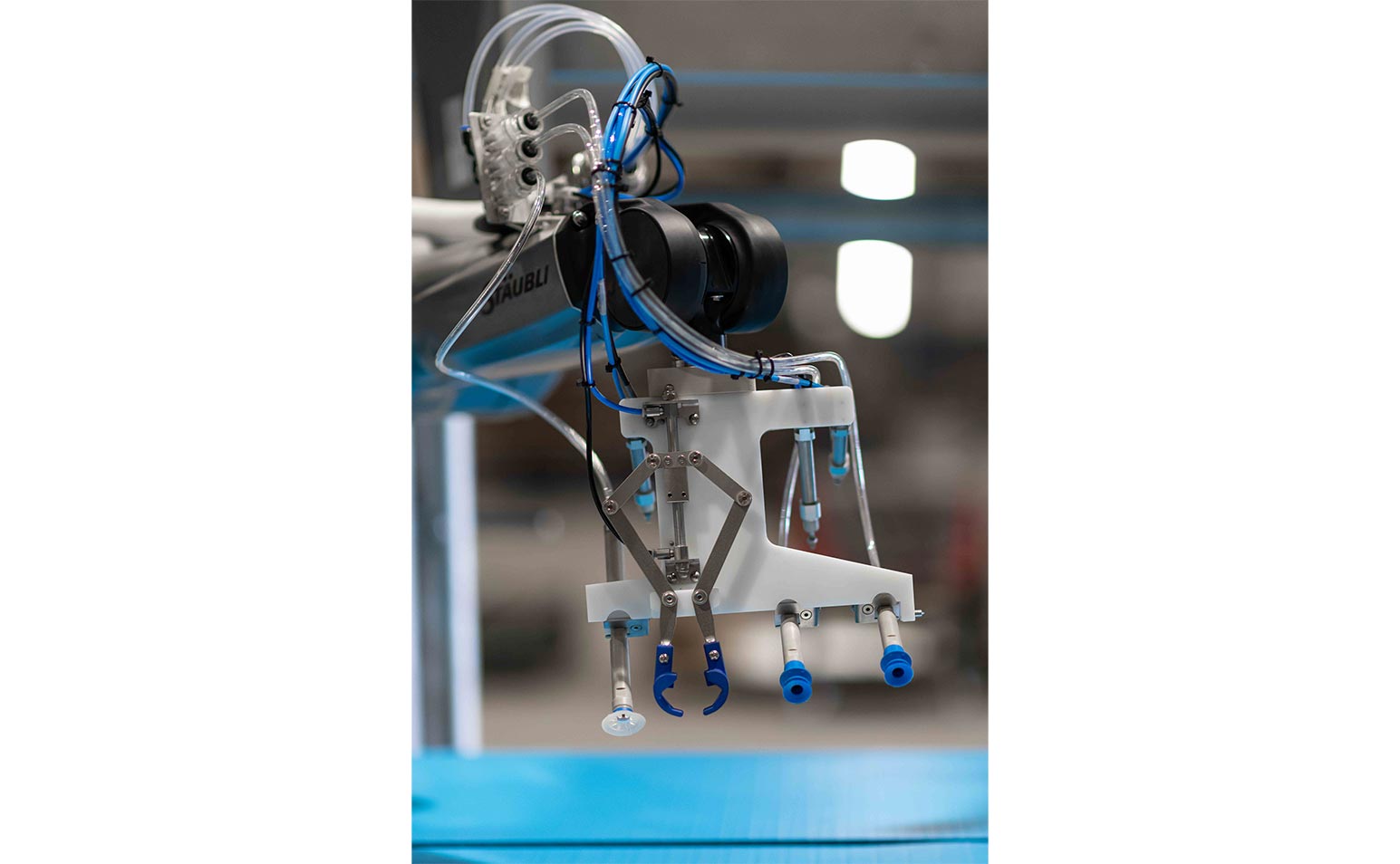

First steps in robotics

First steps in robotics and development of the PINTRO PICK & Place

2018

Further developments of robotics

Further developments of the above lead to the creation of the fully automatic Pick & Skewer machine

2019

Developments improve the P1000 in to P3000 skewering machines

The development of the PINTRO P3000 is came out of the P1000, the capacity tripled.

2020

Cold / clean room

Inauguration of the new > 100m² cold / clean room for tests and demonstrations in a simulated production environment.

20...

Innovation is the common theme

Innovation is the common theme in our timeline. The incentive to innovate is mainly driven by satisfied customers who trust us and believe in our skills and know how.

At this point we’d like to thank our clients for trusting us throughout the years!