Save up to 95% of labour cost

✓ 1 logistical staff member only

✓ Fully automatic feed

✓ Fully automatic evacuation

High capacity & productivity

✓ 15.000 components / hour

✓ Multiple consecutive shifts

✓ Continuous production, even during breaks

Traditional-style product

✓ Quality product

✓ Intelligent picking

✓ Steady skewer quality

Sustained

output

✓ Quick and accurate planning

✓ Fixed production time

✓ Predictable output

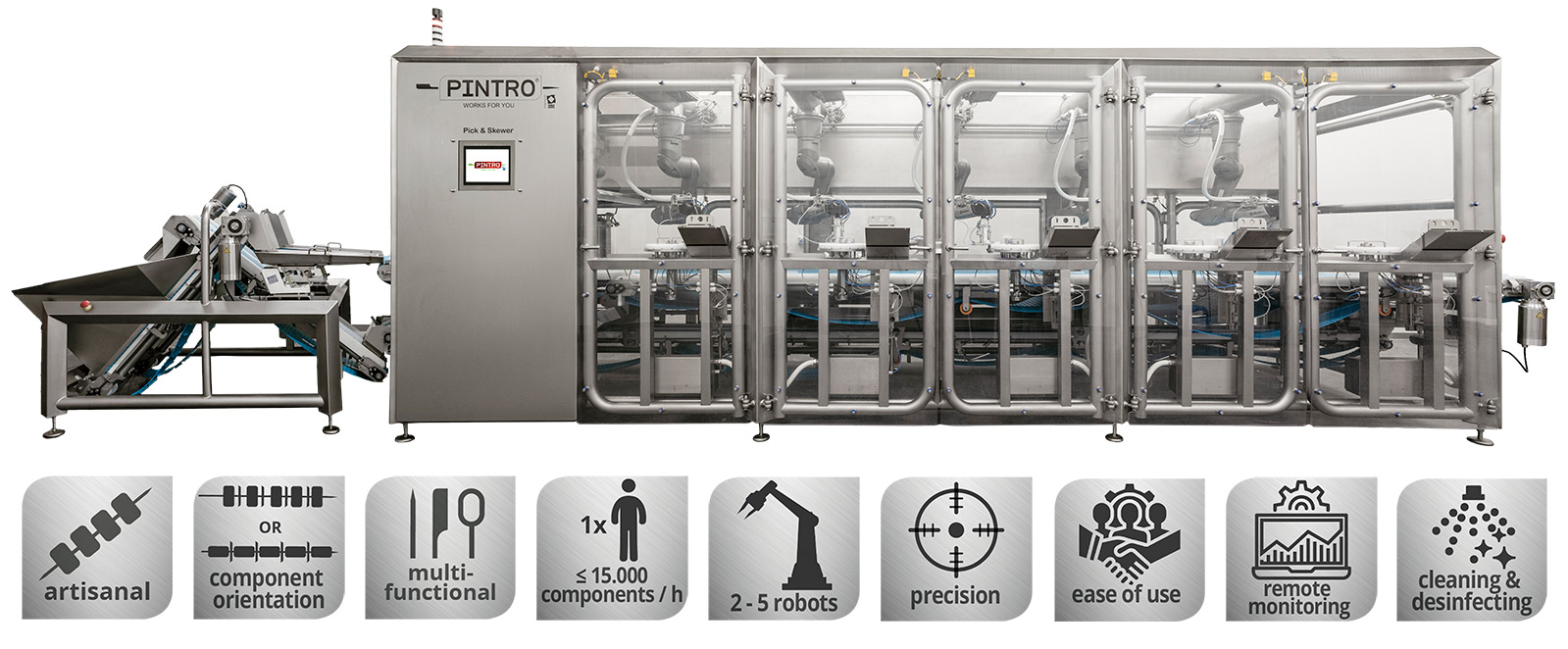

Pick & Skewer

Our PINTRO Pick & Skewer is the world’s first fully automatic skewer machine. The process of feeding the ingredients, the picking & placing on the skewering sticks and the evacuation of the finished products are fully automatic.

The sophisticated vision system permanently monitors the quality of the product. The location and orientation of the ingredients, as well as the position of the skewer tip are closely monitored during the pricking process.

- Minimum staff required

- High productivity

- Traditional-style product

- Steady output

- Multifunctional and flexible

- Hygienic

- Ingenious techniques – Easy operation

Specifications

Save up to 95% labour cost

- Only requires a single logistical staff member to ensure the ingredient supply.

- Fully automatic ingredient feed.

- Fully automatic evacuation of the completed skewers.

High capacity & productivity

- Places up to 15.000 components / hour.

- Works several consecutive shifts.

- Continuous production, even during breaks.

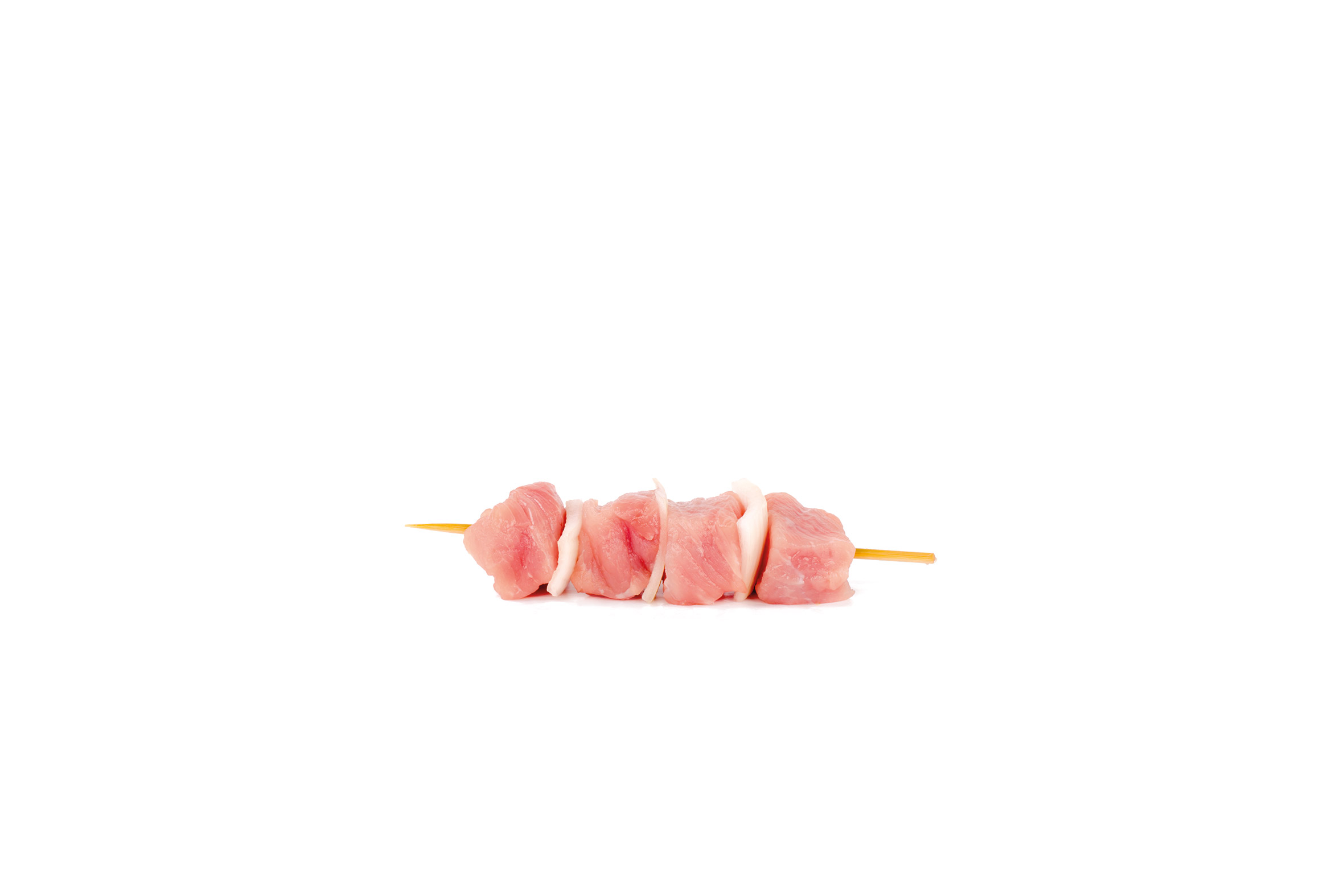

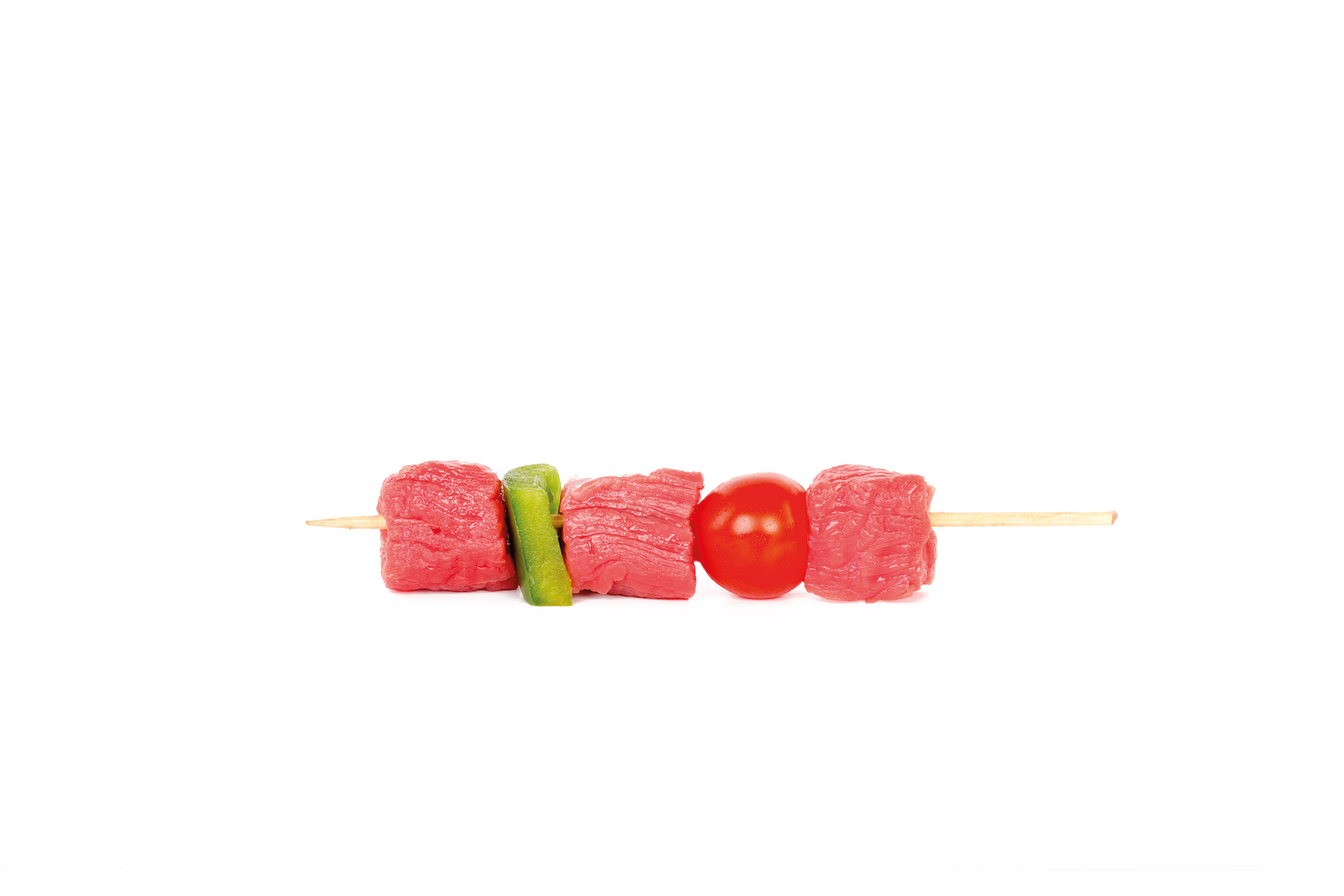

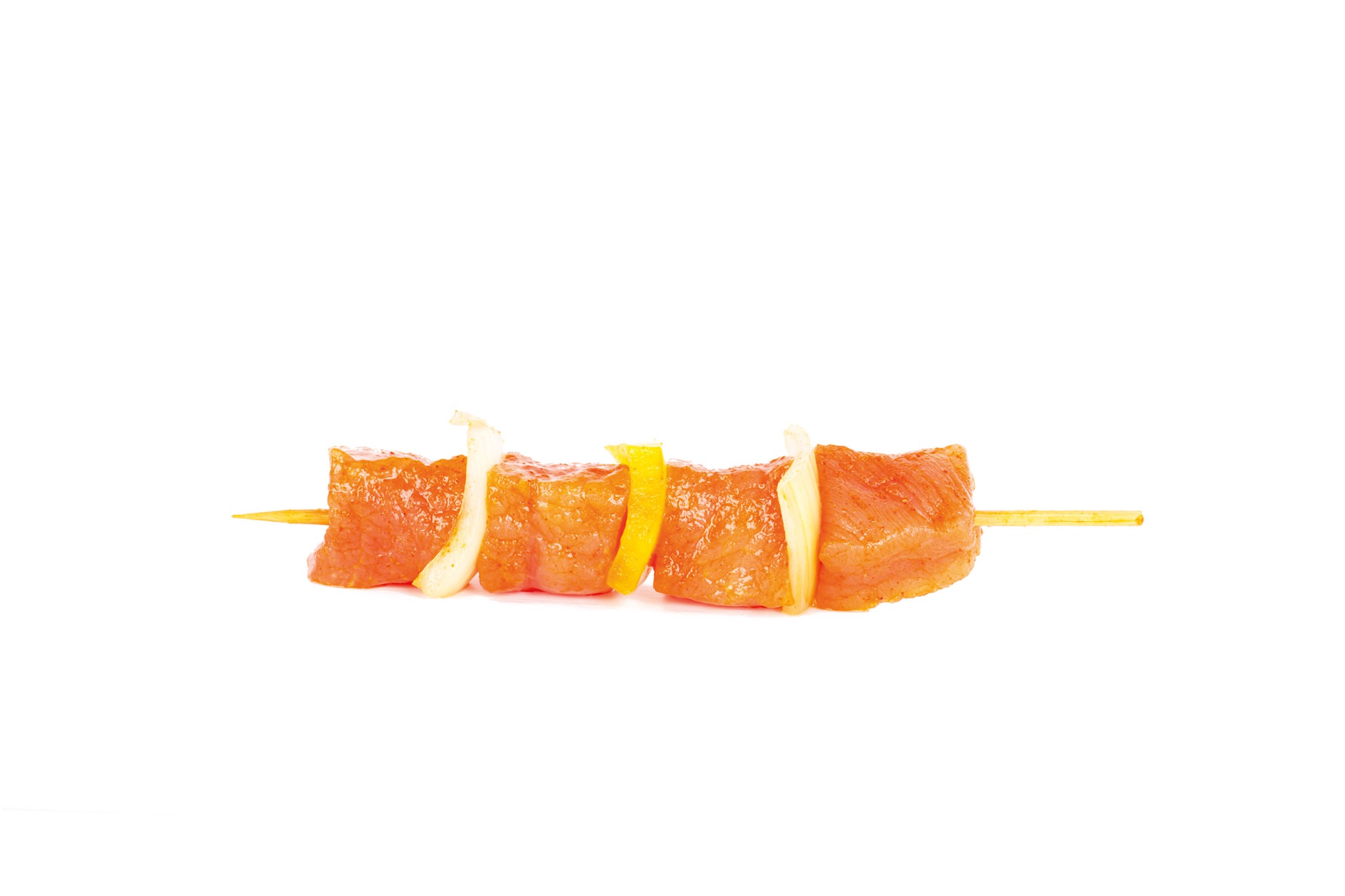

Traditional-style and high quality products

- High quality products:

- Ingenious vision system supervises the quality of the skewers

- Intelligent picking:

- Places the ingredients on the stick in a predefined direction

- Always places vegetables in the same way (e.g. onions convex or concave)

- Always places each ingredient centrally

- Places to an accuracy of 0,1mm

- Spaces between ingredients can easily be defined / adjusted

- Steady quality

- Even look of the skewers

Hygienic

- No or almost no physical contact between ingredients and staff

- Clean In Place (CIP)

- Automatic periodic cleaning and disinfection of the sensitive components

- Automatic rinsing / cleaning of the conveyor belt interiors

- Open installation frame offers easy access during cleaning operations

Steady output

- Quick and accurate planning.

- Duration of the production run is known in advance.

- Output is independent of operators.

Easy to use

- Recipe selection via a HMI touch screen.

- Choice of production depending on:

- – Ingredient supply

- – Number of required skewers

Multifunctional

- 1-20 ingredients / skewer

- Stick length between 60mm – 280mm

- Round sticks – gunshape sticks – stainless steel sticks

- Great variety of choices and skewer / kabob types

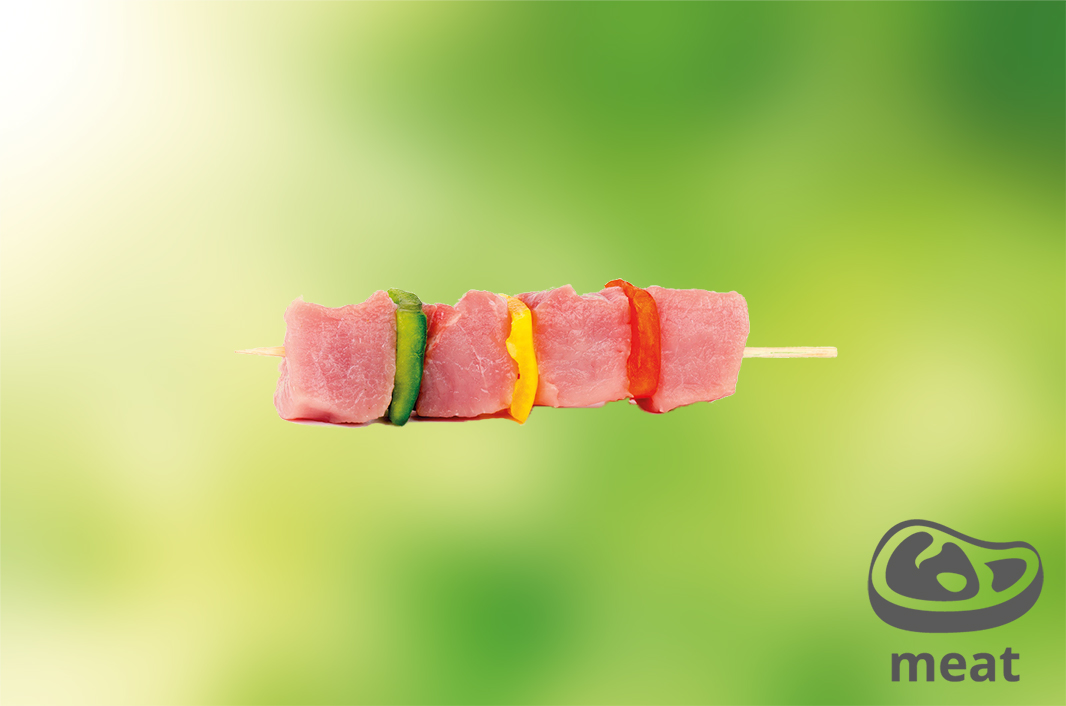

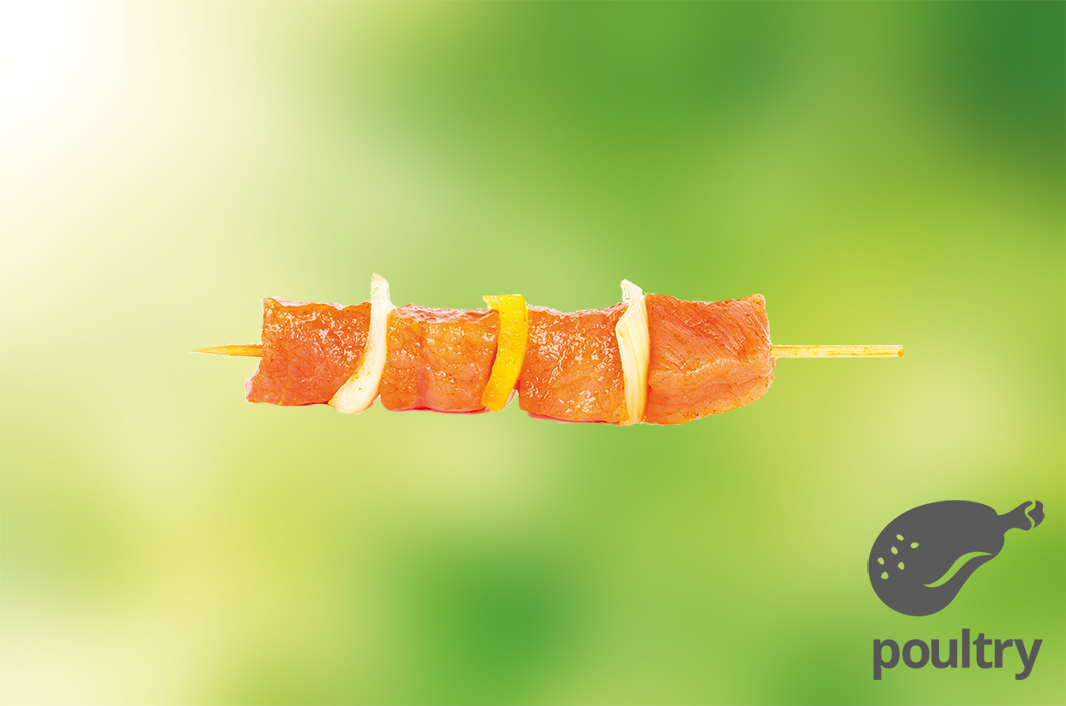

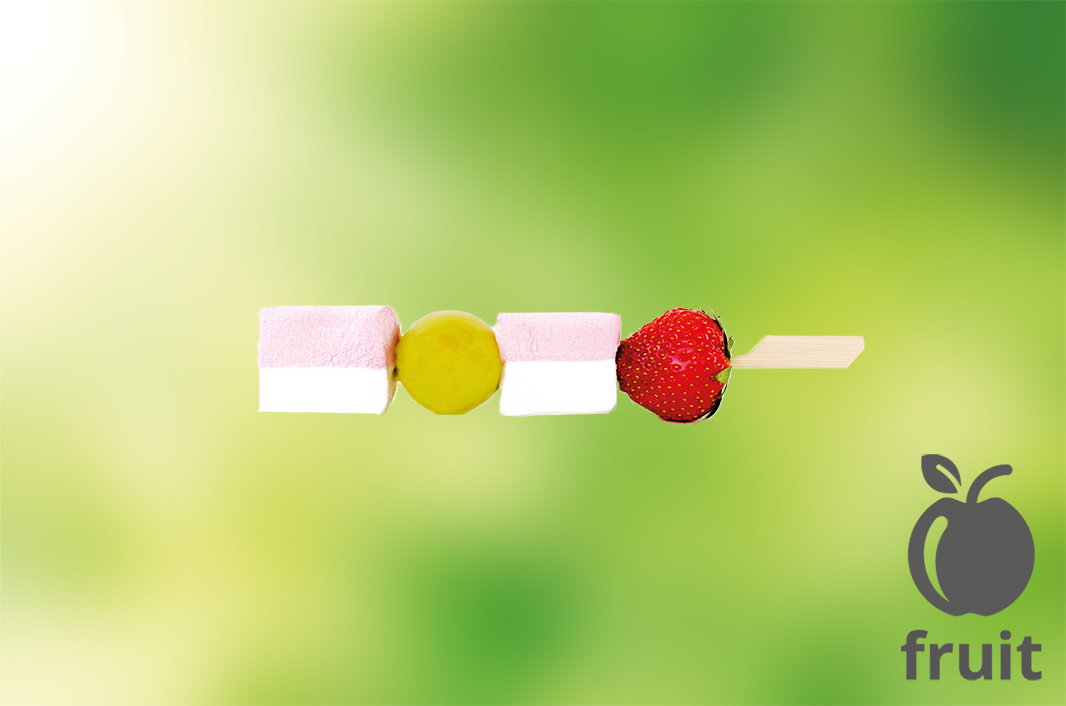

- Meat, fish, poultry, vegetables, candy, fruit…

Fast and safe operation

It only takes a simple touch on the HMI screen for the logistical operator to select a recipe. He also supplies the hoppers with ingredients and resupplies the skewer container with sticks. Touching the start button will launch the machine to fully automatically produce skewers / kabobs.

The ingredients are automatically fed into the machine. They are separated, then transported on a conveyor belt to be presented for picking by the robot. An additional logistical operator may sometimes be needed to separate certain ingredients.

Each robot has a pair of customized grippers that will pick up the ingredients and place them perfectly centred onto the skewer stick. The vision system detects the location and orientation of the ingredients and then calculates and transmits the best position for pricking. For meat chunks this may e.g. mean that we want the piece to be picked and placed lengthwise onto the stick. For vegetables we could define that the robot should only pick and place convex pieces. These settings can be predefined and programmed according to the client’s needs.

The automatic skewer stick selector presents one skewer at a time facing the robot. The tip of the stick is permanently being monitored to ensure central pricking at all times. The completed skewers are transported out of the installation via a conveyor belt to a central collection point.

2-5 robots

Depending on your requirements an installation may consist of between 2 and 5 robots. A single robot can process about 3.300 components per hour.

Evacuation of completed skewers / kabobs

Typically, the completed skewers will be transported out of the installation to a central collection point. Feel free to ask for possibilities to integrate this part into your current infrastructure or process.

Finished product

Meat, fish, vegetables, fruit,…our PINTRO P3000 makes great skewers!

- All skewers / kabobs are even

- Traditional-style look and feel

- Spacing of the ingredients can be defined

- Number of pieces / chunks can be adjusted