[xyz-ips snippet=”breadcrumb”]

Save up to 95% of labour cost

✓ 1 logistical staff member only

✓ Fully automatic feed

✓ Fully automatic evacuation

High capacity & productivity

✓ 15.000 components / hour

✓ Multiple consecutive shifts

✓ Continuous production, even during breaks

Traditional-style product

✓ Quality product

✓ Intelligent picking

✓ Steady skewer quality

Sustained

output

✓ Quick and accurate planning

✓ Fixed production time

✓ Predictable output

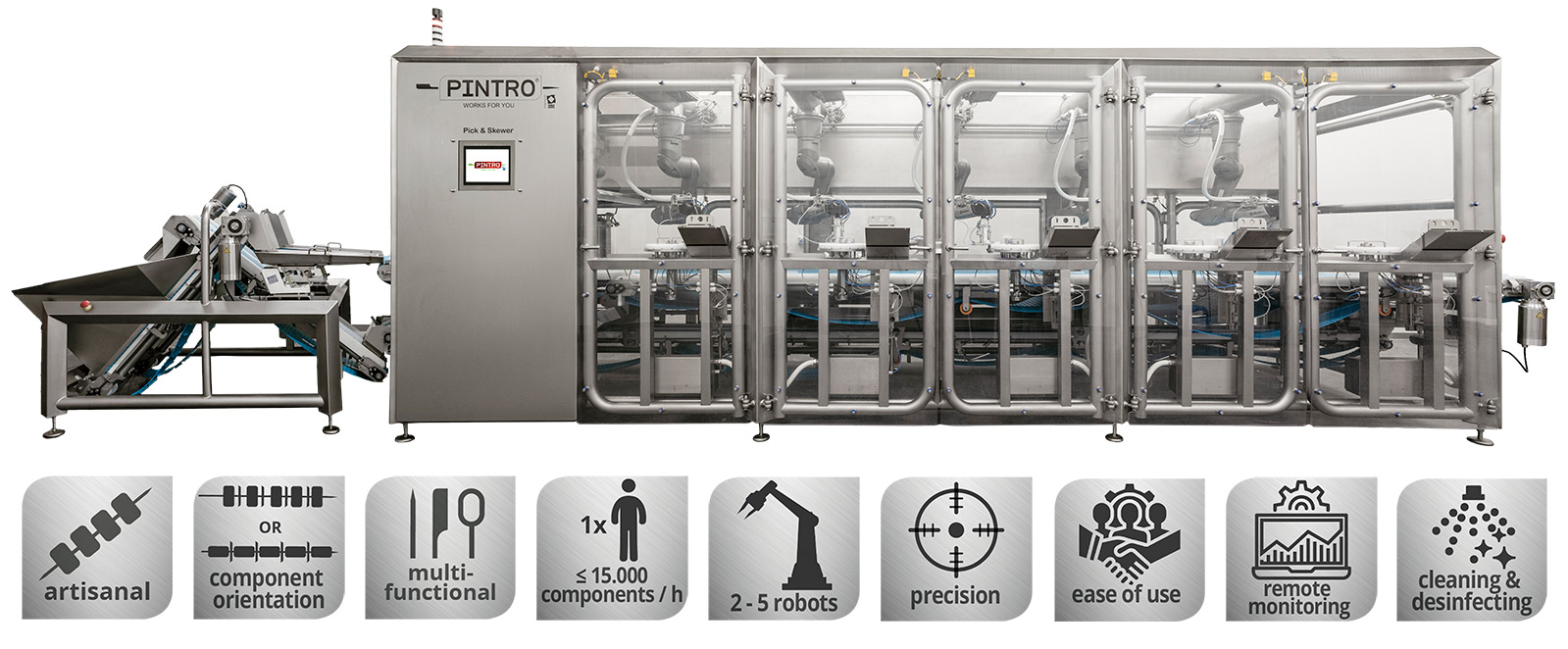

Pick & Skewer

Our PINTRO Pick & Skewer is the world’s first fully automatic skewer machine. The process of feeding the ingredients, the picking & placing on the skewering sticks and the evacuation of the finished products are fully automatic.

The sophisticated vision system permanently monitors the quality of the product. The location and orientation of the ingredients, as well as the position of the skewer tip are closely monitored during the pricking process.

- Minimum staff required

- High productivity

- Traditional-style product

- Steady output

- Multifunctional and flexible

- Hygienic

- Ingenious techniques – Easy operation

Specifications

Save up to 95% labour cost

- Only requires a single logistical staff member to ensure the ingredient supply.

- Fully automatic ingredient feed.

- Fully automatic evacuation of the completed skewers.

High capacity & productivity

- Places up to 15.000 components / hour.

- Works several consecutive shifts.

- Continuous production, even during breaks.

Traditional-style and high quality products

- High quality products:

- Ingenious vision system supervises the quality of the skewers

- Intelligent picking:

- Places the ingredients on the stick in a predefined direction

- Always places vegetables in the same way (e.g. onions convex or concave)

- Always places each ingredient centrally

- Places to an accuracy of 0,1mm

- Spaces between ingredients can easily be defined / adjusted

- Steady quality

- Even look of the skewers

Hygienic

- No or almost no physical contact between ingredients and staff

- Clean In Place (CIP)

- Automatic periodic cleaning and disinfection of the sensitive components

- Automatic rinsing / cleaning of the conveyor belt interiors

- Open installation frame offers easy access during cleaning operations

Steady output

- Quick and accurate planning.

- Duration of the production run is known in advance.

- Output is independent of operators.

Easy to use

- Recipe selection via a HMI touch screen.

- Choice of production depending on:

- – Ingredient supply

- – Number of required skewers

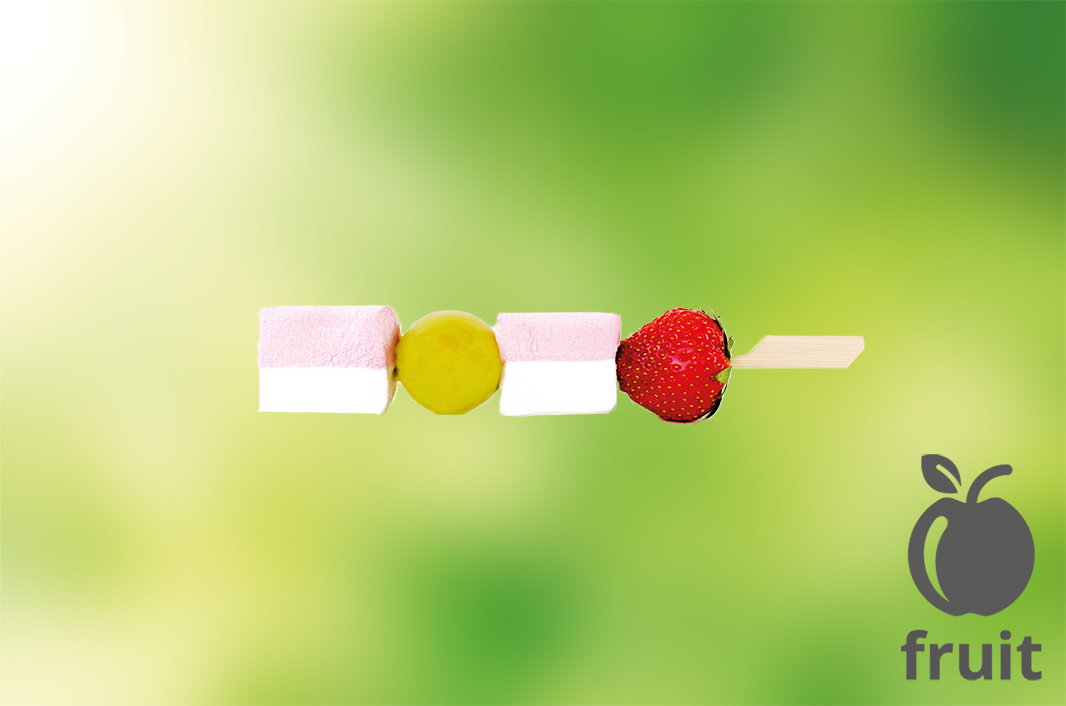

Multifunctional

- 1-20 ingredients / skewer

- Stick length between 60mm – 280mm

- Round sticks – gunshape sticks – stainless steel sticks

- Great variety of choices and skewer / kabob types

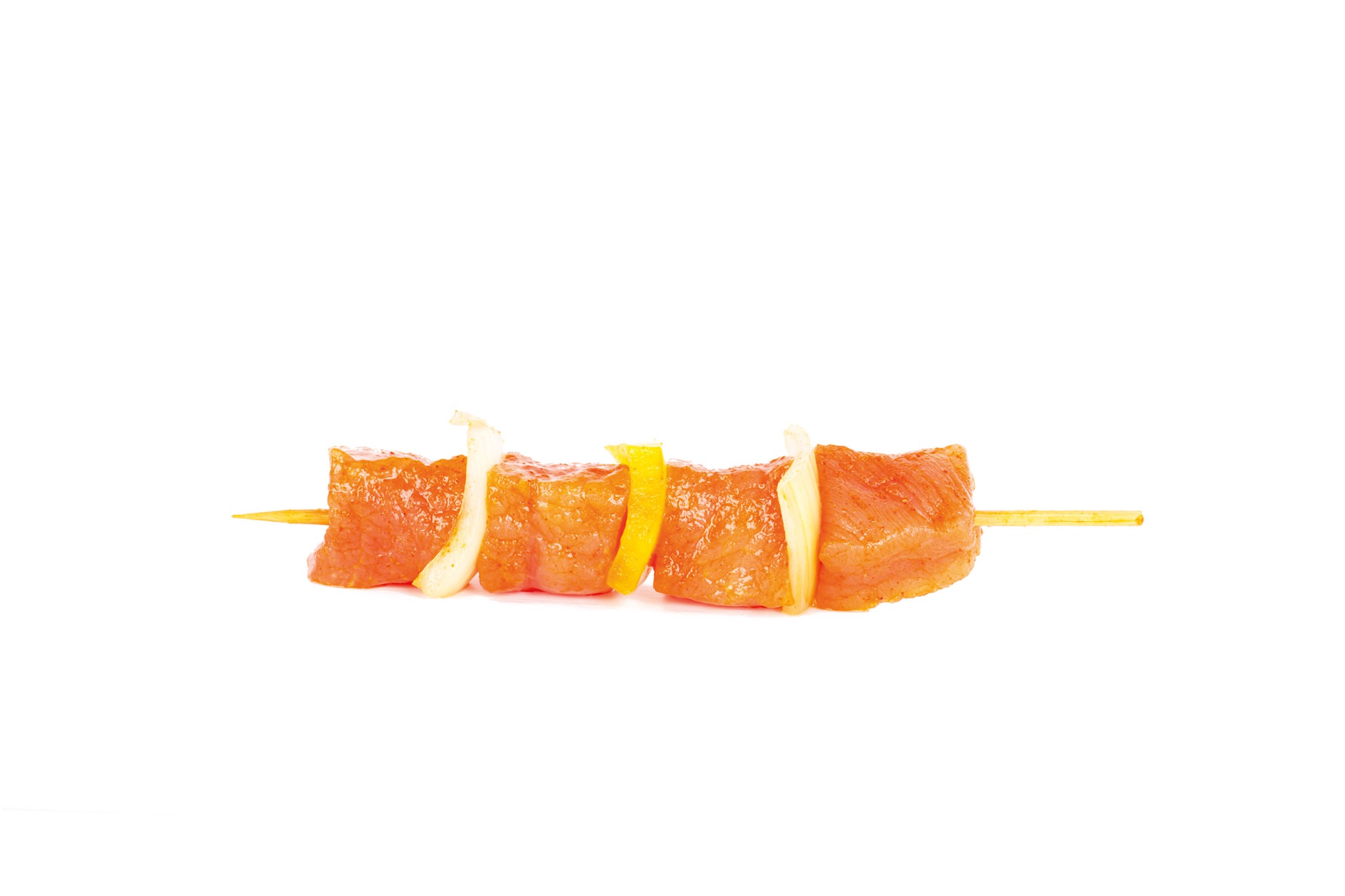

- Meat, fish, poultry, vegetables, candy, fruit…

Fast and safe operation

It only takes a simple touch on the HMI screen for the logistical operator to select a recipe. He also supplies the hoppers with ingredients and resupplies the skewer container with sticks. Touching the start button will launch the machine to fully automatically produce skewers / kabobs.

The ingredients are automatically fed into the machine. They are separated, then transported on a conveyor belt to be presented for picking by the robot. An additional logistical operator may sometimes be needed to separate certain ingredients.

Each robot has a pair of customized grippers that will pick up the ingredients and place them perfectly centred onto the skewer stick. The vision system detects the location and orientation of the ingredients and then calculates and transmits the best position for pricking. For meat chunks this may e.g. mean that we want the piece to be picked and placed lengthwise onto the stick. For vegetables we could define that the robot should only pick and place convex pieces. These settings can be predefined and programmed according to the client’s needs.

The automatic skewer stick selector presents one skewer at a time facing the robot. The tip of the stick is permanently being monitored to ensure central pricking at all times. The completed skewers are transported out of the installation via a conveyor belt to a central collection point.

2-5 robots

Depending on your requirements an installation may consist of between 2 and 5 robots. A single robot can process about 3.300 components per hour.

Evacuation of completed skewers / kabobs

Typically, the completed skewers will be transported out of the installation to a central collection point. Feel free to ask for possibilities to integrate this part into your current infrastructure or process.

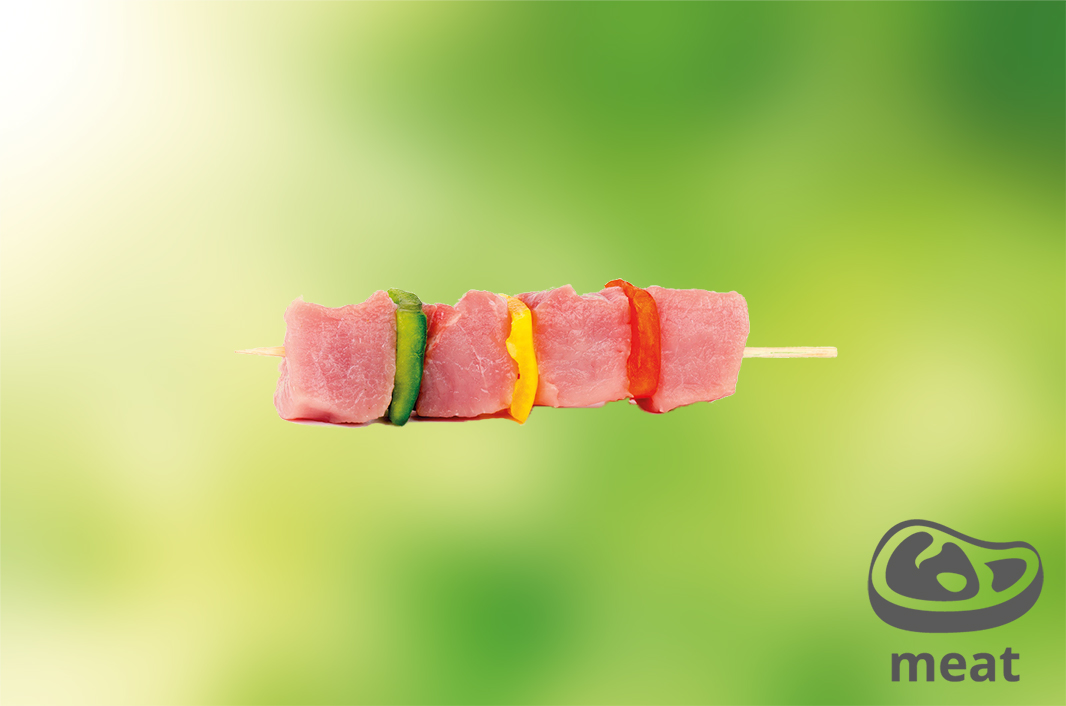

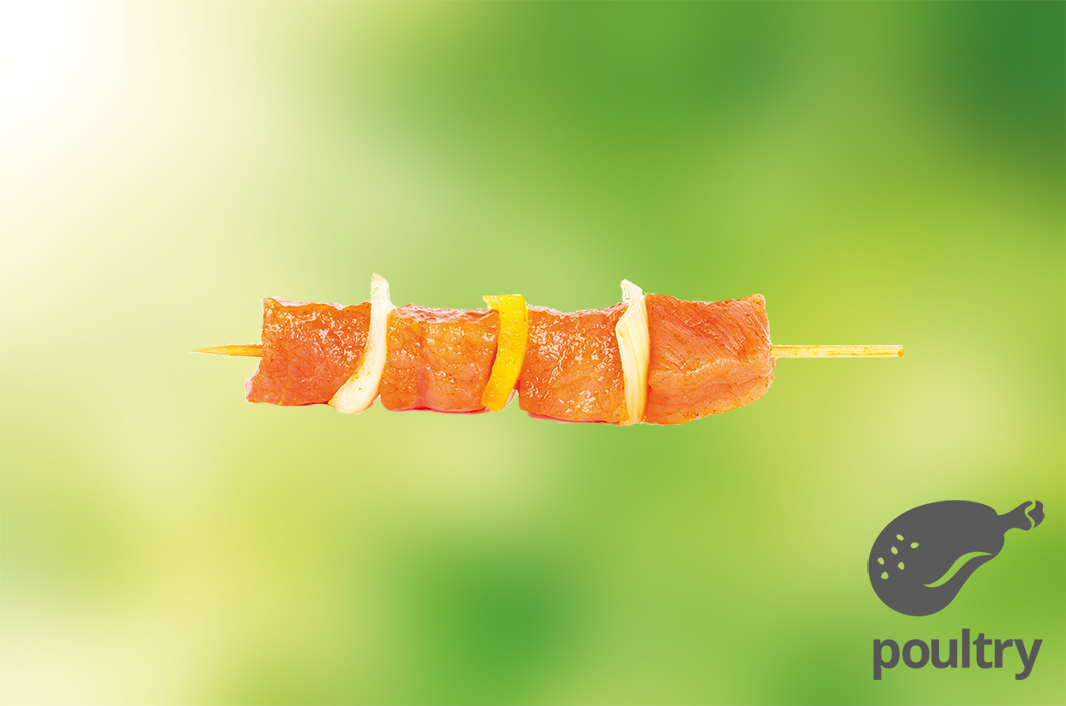

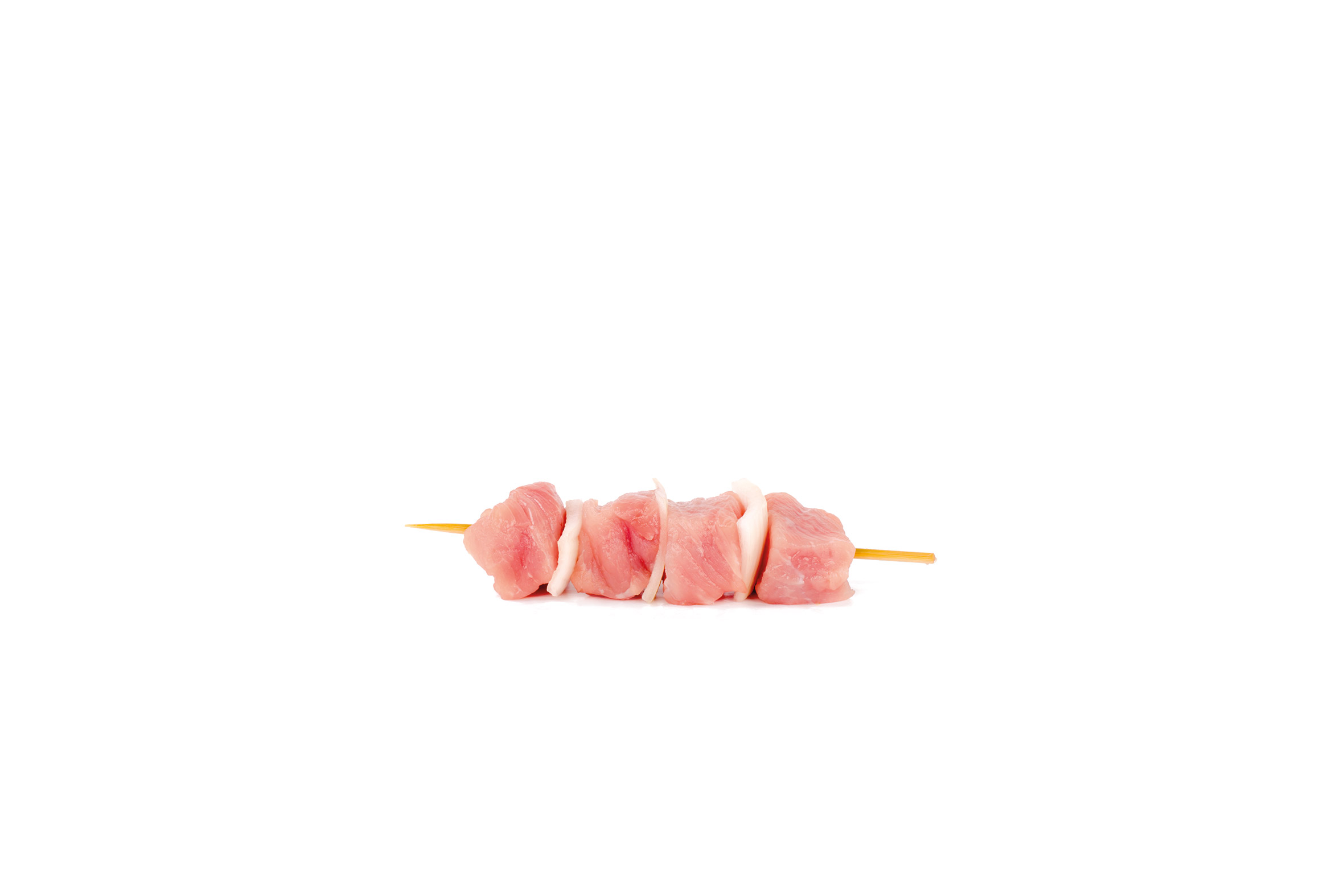

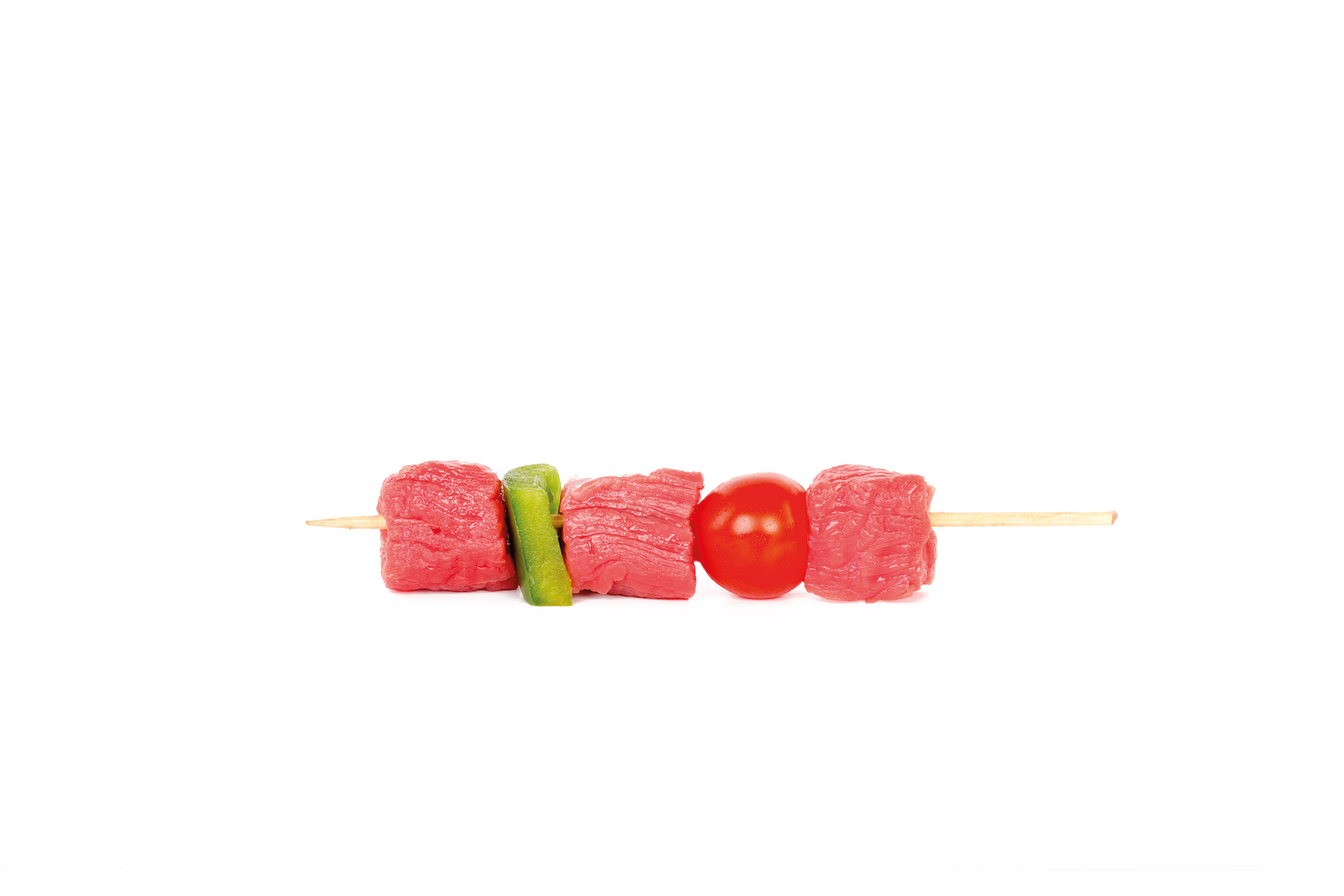

Finished product

Meat, fish, vegetables, fruit,…our PINTRO P3000 makes great skewers!

- All skewers / kabobs are even

- Traditional-style look and feel

- Spacing of the ingredients can be defined

- Number of pieces / chunks can be adjusted

The automation of food production presents immense challenges, not least because of the stringent hygiene standards and the difficulties involved in handling the products. PINTRO bv of Belgium has come up with a novel solution: Their fully automated Pick & Skewer system for the preparation of kebabs is a world first. Stäubli robots with wash-down capability are responsible for handling and precisely skewering ingredients.

Shashlik, souvlaki, kebab and satay – all variations on the theme of skewered meat – enjoy great popularity with consumers. The 160-strong workforce at Beltaste N.V.’s production facility in Morahalom, southern Hungary, produces mainly shish kebabs. In the eyes of automation experts in this field, it is considered a pioneer of “Food Processing 4.0”, i.e. the fourth generation of manufacturing technology. This is because the world’s first fully automatic skewering machine was commissioned there a year and a half ago, and Beltaste has since installed a second one.

High-speed kebab production

To follow how the fully automated Pick & Skewer system functions with the naked eye, maximum concentration is required, as the process runs at a formidable speed. The ingredients are fed in on two conveyor belts at the central point of the production line, with breaded, raw or marinated meat on one track, and onions, peppers, cherry tomatoes or whatever else the recipe calls for on the other. Positioned at the side of the system are the mechanisms in which the ingredients are separated and held ready for horizontal skewering.

The task of the Stäubli robots is to grip the ingredients and ensure that the skewer pierces them exactly through their center. The finished kebabs are then conveyed to the packaging station. The Beltaste system produces between 1,000 and 1,200 shish kebabs per hour without human intervention. And every single one is of top quality.

It was precisely this level of performance that prompted senior management at Beltaste to invest in the world’s first Pick & Skewer system. As Leon Muyshondt, Chief Technology Officer at Beltaste in Morahalom explains, “We spent ages looking for a solution that would increase productivity and at the same time improve quality, but we found nothing suitable. When we saw the Pick & Skewer, we were immediately won over. We believed in the concept and had confidence in the developer and manufacturer.”

Five robots skewer 15,000 separate ingredients per hour

The system was developed by the Belgian company PINTRO bv. Its name is a simplified form of the English phrase “pin through”. Since 2007, this subsidiary of the special equipment manufacturer SMO bv has been producing machinery for the manual or semi-automatic production of kebabs.

The Pick & Skewer has enabled a quantum leap to fully automated production of kebabs – and on a large scale too. Depending on the desired output, a minimum of two and a maximum of five robots pick all of the ingredients and hold them ready for skewering. Beltaste opted for the version with five top-of-the-line Stäubli TX2-60L HE robots. Because one six-axis robot is capable of picking and skewering up to 3,000 separate ingredients per hour, the system achieves a maximum throughput of 15,000 ingredients. At 10 per skewer, that is equivalent to 1,500 kebabs per hour.

Flexible recipe changeover

The robots are guided by vision systems and work their way through the recipes stored in the control system. In doing so, they are not only fast, but also versatile. “We generally vary the recipe every 16 to 20 hours. If this involves swapping grippers, it only takes five minutes thanks to the quick-change systems,” says Muyshondt.

The PINTRO engineers have invested a lot of know-how in the development of the grippers. The result is a combination of mechanical and vacuum grippers that picks multiple different ingredients in a single pass and then pierces them with pinpoint accuracy – otherwise the high level of performance could not be achieved.

Each robot produces its individual complete kebab within seconds. The exact position of each individual ingredient is continuously monitored by the image processing systems. Pieter Weyens, Head of PINTRO: “The ceiling-mounted Stäubli robots grip and position each ingredient with an accuracy of ± 0.1 mm. Precise positioning and alignment are not the only criteria that matter here. It is also important that the kebabs look as if they have been handmade.”

Selecting the robot: hygiene as the deciding factor

In addition to speed and precision, hygiene and cleanability also played key roles in the selection of the robot. The cleaning procedures are robust, as Muyshondt describes: “Twice a day, we run an automatic cleaning and disinfection cycle of the tools, which takes one and a half minutes each time. After every shift, the equipment is thoroughly cleaned and disinfected: first foam is applied, then it is hosed down with hot water from a 40-bar cleaning lance – and that includes the robots.”

The HE (humid environment) version of the six-axis Stäubli TX2 robot is waterproof and thus eminently suited for this requirement profile. It is fully encapsulated and withstands the cleaning run without any impairment of function. Even frequent and intensive cleaning processes, such as those prevalent in the pharmaceutical and food industries, do not lead to any reduction in service life. Further, HE robots are designed to operate even in sensitive environments. Their wash-down compatible hygienic design is considered unique.

The robots used in the skewering system are also lubricated with food-grade NSF H1 oil. “The robots are subjected to a heavy workload, because they perform a lot of rapid and delicate movements. So the lubricant has to be efficient and at the same time meet the requirements of the food processing industry,” says Muyshondt. The H1 oil that Stäubli developed in collaboration with an established lubricant manufacturer meets these criteria perfectly.

Simple programming, together with even simpler operation

Coordinating image processing and robot movements at this speed and with the requisite precision also places high demands on the robot controller. This is another area in which the machines score high marks: Stäubli CS9 controllers are known for their high performance and also for excellent connectivity. A further advantage is their simplicity of programming.

Users of the Pick & Skewer have it even easier, as Muyshondt explains: “The employee simply selects a recipe, loads the ingredients, and presses the start button – job done!” While kebab production is running, ingredients can be added. And the image processing systems also oversee the quality control of each individual skewer.

A concept with many advantages

In the Pick & Skewer, PINTRO has developed a worldwide first for the food processing industry, clearing high hurdles along the way – for example, with the design of grippers that pick and place onion slices and cherry tomatoes at speeds almost too fast for the human eye to follow. Because the system handles raw meat, the entire process must be carried out under the strictest hygienic conditions, which is thankfully not a problem for Stäubli HE robots.

From the perspective of the early adopters, the concept offers clear advantages. Muyshondt is enthusiastic: “The quality of the kebabs is consistently high. The ingredients are skewered precisely, and we have a free choice of ingredients. Cleaning and disinfection times are extremely short, and the robots can be hosed down at the same time. This is the future of kebab production.” With the first Pick & Skewer line having been such a huge success, a second one has recently gone into operation at the Beltaste factory in Hungary.